Delivers world-class dry ArF performance and productivity through Streamlign platform innovations

The semiconductor industry is transitioning to development and high volume manufacturing of next-generation process devices, with the most critical layers exposed using immersion scanners with multiple patterning. In addition, as design rules for new technologies become more challenging, many layers will need to transition from KrF to ArF dry processes. This necessitates dry 193 nm scanners that deliver high productivity with overlay accuracy comparable to immersion systems, as well as exceptional system stability and matching capabilities.

The NSR-S322F is the industry-leading dry ArF scanner for high volume manufacturing. It combines the proven Streamlign platform with continuous technology advancements to satisfy the requirements of the most demanding non-immersion 193 nm layers.

Enables superior yield with overlay accuracy ≤ 2 nm

The Nikon DUV S322F scanner utilizes the proven Bird’s Eye Control system, which uses laser encoders along with conventional interferometers to accurately determine wafer position time after time. This is coupled with enhanced lens distortion and wafer holder thermal management solutions which improve focus control.

In addition, Phase Shift Focus Monitor (PSFM) across wafer focus control of 12.0 nm (including edge shots) has been achieved.

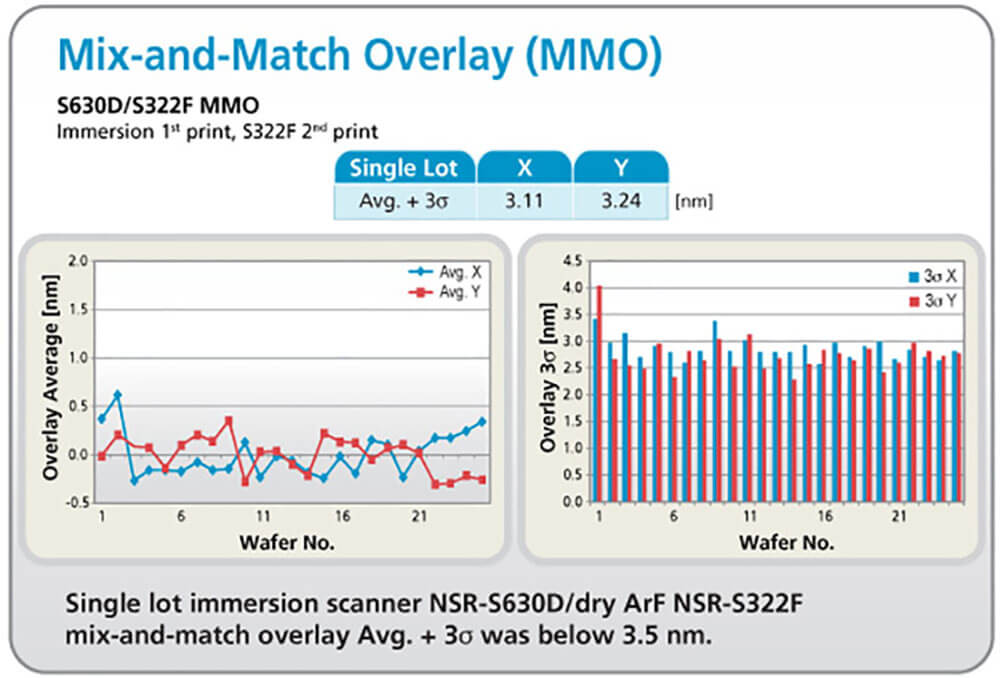

Maximizes manufacturing flexibility with mix-and-match overlay ≤ 5 nm

Mix-and-match overlay (MMO) is vital for advanced applications, and compensation functions that adjust the grid and distortion of one scanner to another are essential for heightened matching performance. The S322F supports advanced shot distortion correction capabilities provided by Dynamic Matching Adjustment Control. Correction for k9 trapezoid shape and k17 c-shape distortions across the scan slit, as well as k18 c-shape distortion compensation that allows distortion correction along the scan slit are available. This function successfully mitigates distortion variation, even under high dose conditions, to optimize performance for the most demanding mix-and-match requirements. The NSR-S322F enhances scanner matching capabilities and production flexibility, delivering mix-and-match overlay performance below 5 nm.

Mix-and-match overlay between immersion and dry scanners is of particular importance. MMO data collected using the NSR-S630D immersion scanner for the first print, and the S322F for the second print showed lot MMO Avg. + 3σ performance below 3.5 nm.

Ensures excellent imaging with 0.92 NA lens and advanced tool control capabilities

The S322F features an enhanced 0.92 numerical aperture projection lens to enable resolution of 65 nm or better with optimal CD uniformity. Superior materials and proprietary manufacturing technology provide a virtually perfect lens that is essentially flare free and has the industry’s lowest aberration levels. The S322F delivers lower lens distortion and employs the iMAC lens controller to provide sophisticated lens tuning capability. This is coupled with POLANO polarization control, which enhances image contrast without any loss of illumination power or throughput.

The NSR-S322F also enables a number of advanced tool control solutions, which further enhance tool stability and on-product performance. The Zeroing Autofocus function performs automated periodic machine calibration that improves scanner stability with machine-specific autofocus corrections. Similarly, the Zeroing XY function can perform automated periodic machine calibrations and machine-specific grid corrections to further enhance overlay stability. In addition, CDU Simulator makes it possible for the scanner to correct for other process window detractors. It provides high-order dose and focus adjustments to reduce residual CD errors both across the shot and across the wafer.

Provides optimal affordability with ultra-high throughput up to 250 wafers per hour

Chipmakers will utilize dry lithography as much as possible to balance multiple patterning costs. Therefore, S322F throughput is a critical factor in making advanced processes cost effective for manufacturing. The NSR-S322F employs sophisticated dry sequencing, and its wafer stage uses optimized scan speed and acceleration capabilities to reduce exposure time. In addition, the Stream Alignment wafer mapping system utilizes multiple alignment microscopes (Five-Eye FIA) and a wide area autofocus sensor (Straight Line Autofocus) that spans the wafer to pre-scan the substrate during loading−dramatically reducing wafer overhead time. Together, these innovations enable throughput ≥ 230 wafers per hour (WPH) using 96 exposures/wafer, with optional throughput up to 250 WPH possible.

| Wavelength (nm) | 193 |

| Lens-NA | 0.92 |

| Exposure Area (mm) | 26 x 33 |

| Reduction Ratio | 1/4 |

| Resolution (nm) | ≤ 65 |

| Mix-and-Match Overlay (nm) | ≤ 5 |

| Throughput: | |

| 300 mm (96 exp fields) | ≥ 230 (≥ 250 Optional) |

| Wafer Size (mm) | 300 |