High precision frontside and backside overlay metrology capabilities for MEMS and leading-edge power devices

Nikon BSM systems provide frontside (top) and backside (bottom) overlay metrology capabilities. They deliver optimum accuracy by using fixed frontside and backside microscopes to measure both sides of the substrate. Then, by comparing deviations in the measured coordinates of the alignment marks between the frontside and backside, the BSM systems can determine:

• X/Y offsets and X/Y scaling

• Substrate rotation

• Perpendicular (substrate orth) offsets

The BSM results can then be incorporated in the stepper exposure recipe parameters to maximize the device processes’ yield.

Flexible substrate handling and excellent accuracy independent of substrate thickness

These Nikon metrology systems are capable of handling a variety of substrates, including bonded wafers. They use X and Y interferometers to deliver optimal accuracy and can accommodate substrate thicknesses of 60 μm to roughly 1100 μm. The BSM-1 (formerly known as BSM-200) and BSM-300 systems provide front to back measurement repeatability 3σ of 100 nm and accuracy IMI +3σ of 150 nm. The BSM-1 system can accommodate wafer sizes up to 200 mm, with BSM-300 used for wafer sizes up to 300 mm. Please submit any inquiries to accountsupport@nikon.com.

The Nikon BSM system design provides optimal accuracy that is independent of substrate thickness. In addition, the BSM fixed optics method eliminates the need for wafer rotation and thereby maximizes metrology throughput with the BSM-1 able to process up to 50 (200 mm) wafers per hour and BSM-300 throughput equaling 35 (300 mm) WPH. In contrast, other designs may require rotating (flipping) the sample wafer in order to refocus and then re-measure, which can complicate the process and impact throughput.

Efficiently determine front to backside wafer alignment correction parameters for use by steppers to minimize residual overlay error

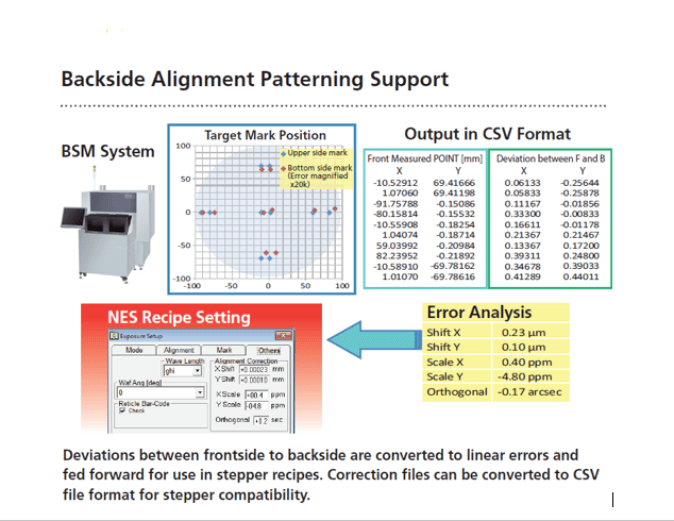

The BSM systems operate within a Microsoft Windows environment for an easy and user-friendly GUI, as well as simplified operation and networking functions. Deviations between frontside to backside measured by the BSM are then converted to linear errors, and subsequently able to be fed forward for use in stepper exposure recipes. Exposure corrections can be sent directly to Nikon MEMS steppers to quickly optimize frontside and backside overlay accuracy. Additionally, BSM output results can be converted to CSV file format for use with other exposure tools as well.

Process layers of MEMS and leading-edge power devices often require enhanced overlay accuracy and patterning on both sides of the substrate. The high accuracy Nikon BSM-1 and BSM-300 systems provide advanced frontside and backside overlay metrology capabilities in a small footprint tool platform.

| Repeatability 3σ (nm) | 100 |

| Accuracy (M + 3σ) (nm) | 150 |

| Wafer Handling | BSM-1: With 2 port autoloader, up to 200 mm BSM-300: With 2 port FOUP opener, up to 300 mm |

| Throughput | BSM-1: 200 mm: 50 WPH BSM-300: 300 mm: 35 WPH |